Mold Design & Development

To get from an idea or concept to an injection molded plastic product that you can sell requires several steps. There are four basic steps to go from conception to a finished molded part.

Each step requires a different set of skills and knowledge. The key to developing a plastic injection molded product is to smooth the transition between each step in the process. The best method to achieve this is to use a single source for all of the steps within China.

Step One: Design

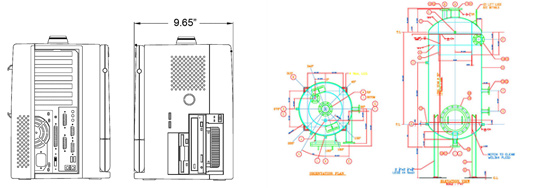

This can be the most important step in the process, yet many entrepreneurs try to skip over design or find a short cut around design. Industrial designers use CAD systems along with years of experience and knowledge to transform your idea into a three-dimensional computer model. These designers must understand plastic, and the strengths and weaknesses of each type to determine what is best suited to your product application. It is also to have the knowledge to bridge the gap between your idea and a moldable product. With the use of modern day CAD/CAM systems, it has become universal that to take your product to the next step of prototypes and tooling, you must have a CAD model first.

Finding a designer is easy - finding a good designer can seem impossible. The best source for finding a designer to work with molding and tooling shop side-by-side is a company like Seal. We have experience working with designers and know which ones are best at understanding your idea. A great designer not only can transform your idea into a CAD file, but can save you cost in tooling costs with a good plastic part design.

Step Two: Prototypes

A prototype is a real life physical sample of your idea or part. Having a prototype serves two functions. First, having a prototype allows you to test you idea and proves out the functionality of your product. If you need any modification of your design, this is the time to do that. Tooling is expensive and you really want to be absolutely sure of your finished product before you start building a tool. Spending a few dollars to make changes at this step will save the thousands of dollars of cost to make changes in the tooling step. Secondly, a prototype allows you to get started on the marketing of your product. They can be used for photographs for the web or brochures, and they give you a physical example of your product to hand to potential customers. It's always easier to say "here is my product" rather than try to explain what you think it will look like to a potential customer or investor.

Prototypes have come a long way in recent years with the advancements in systems like SLA, SLS, FDM, or 3DP. The systems take a CAD Model, and in a few hours, produce an actual finished part you can hold and use. This is a good way to prove your design for what is typically only a few hundred dollars per part, while saving you potentially thousands of dollars in tooling costs later. Also, the ability to get a jump start on your marketing plan by having parts in hand can be invaluable.

Step Three: Tooling

Now that you have a proven design and product, it’s time to start tooling for production. Tooling can be one of the most expensive steps in the process. Having a dependable tool builder is essential. Seal located in Shenzhen, China has many experienced and prequalified mold and injection shop that we have worked with for many years. Tooling can be very complicated or quite simple depending on the part you are trying to make. If you want to end up with a quality product, you need to start with quality tooling.

Injection molding tooling is a steel or aluminum block machined with cavities in the shape of your plastic part. Tooling can be single cavity which means that it makes one part at a time, or can be multiple cavities that makes several parts at a time. Your volume requirements and cost requirements will determine how many cavities your tool will need to be. The more cavities your tool has, the higher your tooling costs will be; however, more cavities mean lower part costs and less time to mold the required product.

Tooling is relatively expensive, costing as little as $5,000 going up to $50,000 or more. Again, a good part design can have a great effect on controlling tooling costs. Injection tooling typically will be capable of running at least a half million cycles with no degradation of part quality and sometimes more than a million cycles with proper care.

Step Four: Molding Finished Product

Molding is the point where your great idea or invention becomes reality. Plastic injection molded parts are relatively inexpensive yet that doesn't discount their importance to you. There are many different materials, all with different properties available to enhance your product. Color choices are endless. A typical run of parts may be as few as a hundred parts or as many as a million. The price of a molded part is a combination of raw material costs plus the time required to mold the plastic part. "Cycle time" is the term used to describe the amount of time it takes for the molding machine to make a complete cycle producing a "shot" of parts. It may be one part if you have single cavity tooling or many parts if you have multiple cavities. Obviously, the more cavities you have, the lower your "per part" cost will be. It is important to have a company that understands the importance of your product.