Manufacturing Qualification & Selection

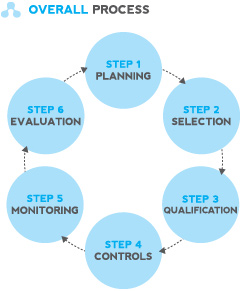

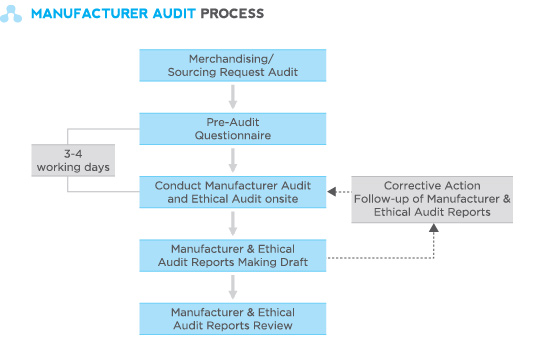

Seal utilizes its sizable portfolio of manufactures with long standing relationships to develop comment and assemblies that are common to all electronic projects. Pub fabrication, mold tool and injection shops, printed and box manufacturers, power supply manufacturers, cable and harness manufactures are example of pre-qualified manufactures that Seal utilizes on a regular basis. However, not all projects can utilize Seal’s existing pre-qualified manufacturer base. It is often necessary to qualify new manufactures in China and elsewhere in Asia. Under these circumstances, Seal will source new manufactures that have existing expertise in a specific product similar to the new project in question. The manufacturer(s) will then be subjected to rigorous audits both on capability and ethical basis. The audit process is summarized below along with the audit standards typically used by Seal. The audit is just one of the steps in qualifying the project to the right manufacturer as after audits are found to be satisfactory, the process of cost benchmarking is then conducted to determine if the manufacturer is competitive in the market place.

The basic steps of audit are:

- I. An initial meeting with manufacturer management to explain briefly the purpose and procedures of audit.

-

II. A manufacturer physical audit of all manufacturing areas including: facilities, production floors, dormitories, canteen, etc.

- III. Document review of related documents pertaining production qualities, facilities and compliances.

- IV. A personal interview between our auditors and randomly selected employees from manufacturer.

-

V. A concluding meeting with manufacturer management to discuss any findings and propose action plan.

Seal Audit standards

- I. Quality Assurance System –Based On ISO9001: 2000/TS16949; MIL STD 105E: BS 6001

- • RoHs Compliance Audit Standard

- • Social Accountability/Human Rights Compliance System-Based On

- II. SA8000 Involved In ETI/CITI /COC/BSCI/CSR/CSCC/CS9000

- • Occupation Safety and Health Management Issue-Based On

- III. OSHMS18001

- • Local/ National Labor Law Regulation and Health & Safety for Workplace.

• C-TPAT Expectations